Climbing gardens don't drill themselves: What effort is actually involved in setting up and maintaining climbing gardens? And who takes care of these construction sites on the mountain? Out and about with a helmet, hammer and drill.

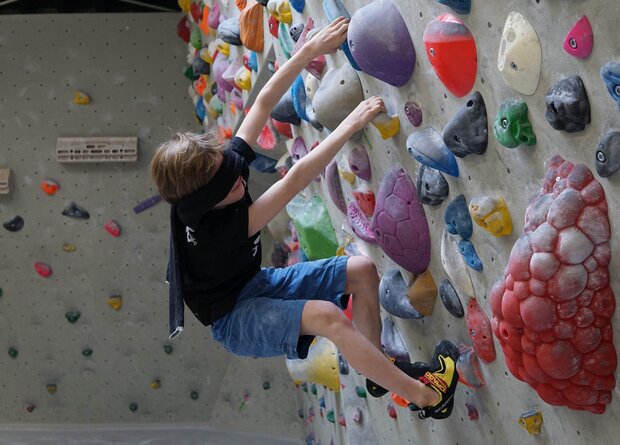

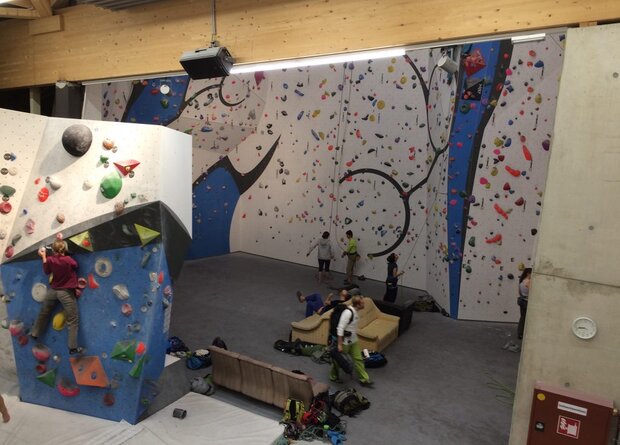

If we're honest, it's usually like this: you arrive at a climbing garden with good friends, talk happily, get on the first route, clip the standing carabiner, abseil down again, all's well. Rarely do you ask yourself how the pitons that you so unhesitatingly clip into the rock actually get there, trusting them blindly. But nature is not a climbing hall: especially in winter, with extreme temperature fluctuations over the seasons, with precipitation, with wind ... a mountain range is constantly changing.

The quality standards that Climbers Paradise Tirol has set itself are probably unique in the Alps. But a climbing garden doesn't just have to be bolted once, it also has to be continuously maintained and looked after. Today we are out and about with someone who does this for a living: mountain guide Martin Gstrein from Karres, who specializes in clearing rocks and maintaining climbing gardens and via ferratas.

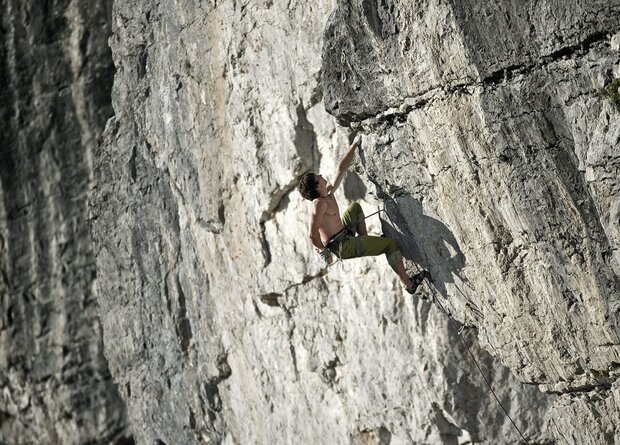

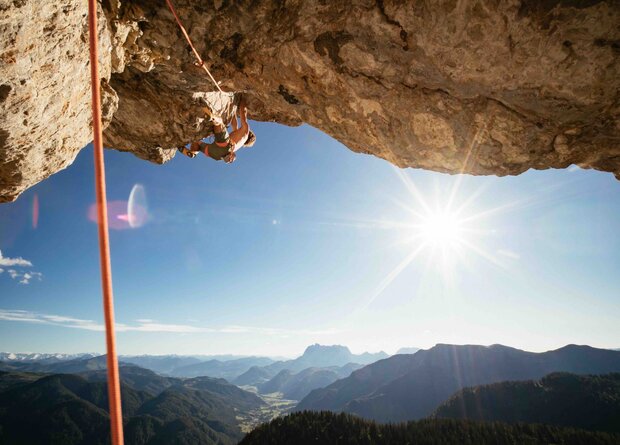

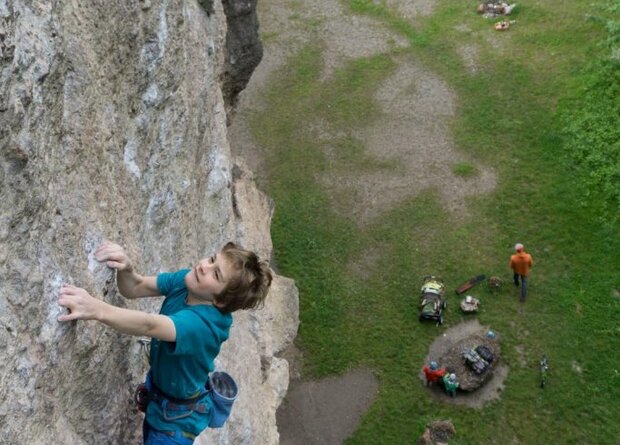

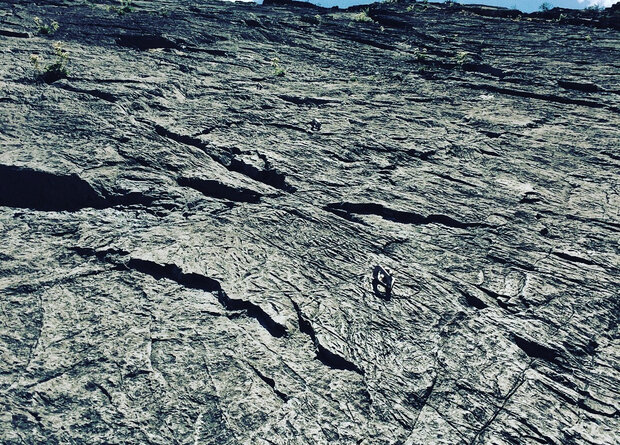

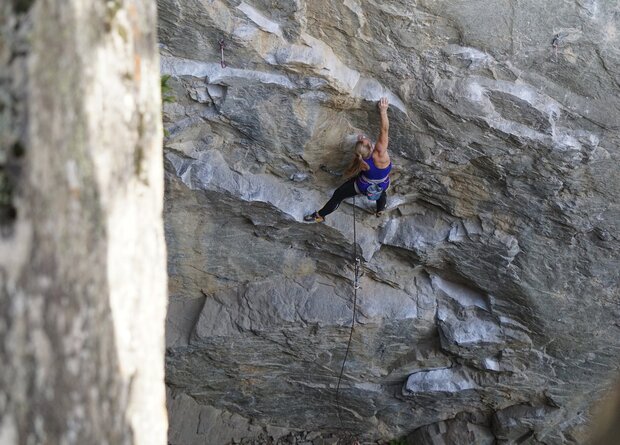

His workplace today: the Rote Wand directly above his home village in the Tyrolean Oberland, a climbing garden with many routes of moderate difficulty and an idyllic location, which he has of course known like the back of his hand since he was a child. There is still snow on the high mountains in the background, but the sunny aspect means you can climb here comfortably in a T-shirt. Today, the Karres / Rote Wand climbing garden is to be made fit for the season again after a long winter. So that the bolts can actually be clipped without hesitation.

Safe and well-maintained climbing gardens don't just happen on their own. Trained maintenance personnel such as Martin Gstrein are responsible for annual maintenance in the individual regions.

The way to the wall

Instead of a walking stick, Martin Gstrein has a rough rake in his hand. The work begins as soon as he reaches the approach: many stones have been left lying on the narrow access path over the winter and need to be removed. A first sign that not everything seems to be quite solid in the limestone bar above Karres.

When we arrive at the actual climbing garden, Martin first stretches a red and white barrier tape between a bolt and a small pine tree. "Unfortunately closed today", it says, because there will be a construction site here today.

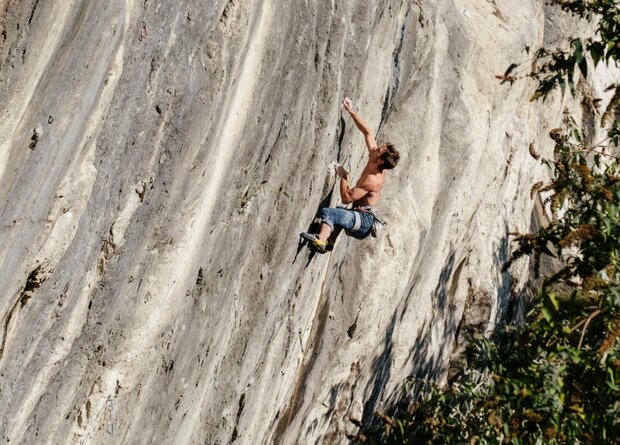

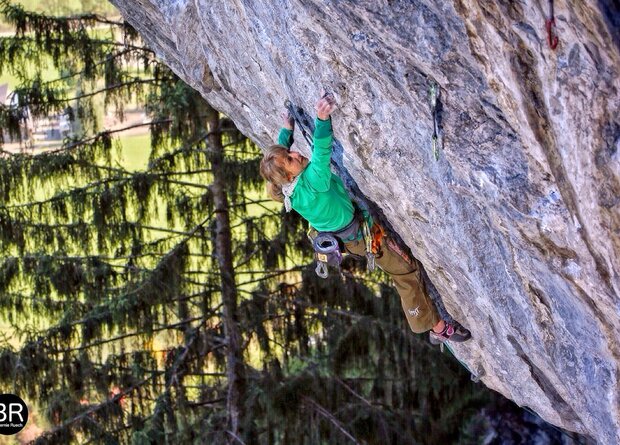

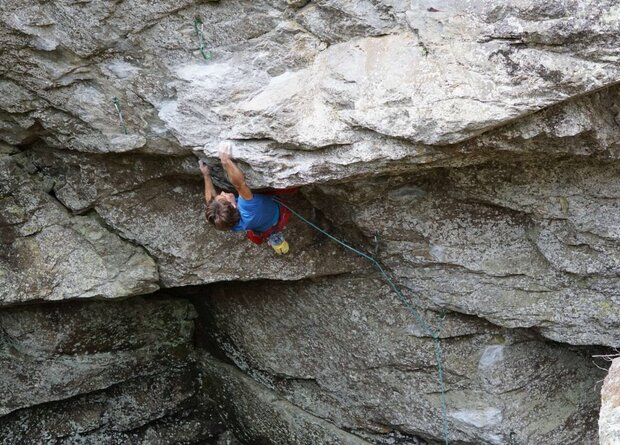

But then it's time to unpack the rope and put on the climbing harness: Assessing the situation, or rather the routes. This gives you an idea of why a good climbing garden renovator should also be a good climber: he first has to get up to the belay, he has to have a feel for the area and the rock.

Martin's climbing harness today has much more on it than just the quickdraws that you normally need for sport climbing here: Hammer, drill, flex, wrench. A vertical construction worker.

The work for our maintenance staff begins on the way to the rock. Namely with the alignment of the access route. For Martin Gstrein, "his rake" is part of the basic equipment.

The belay must be right

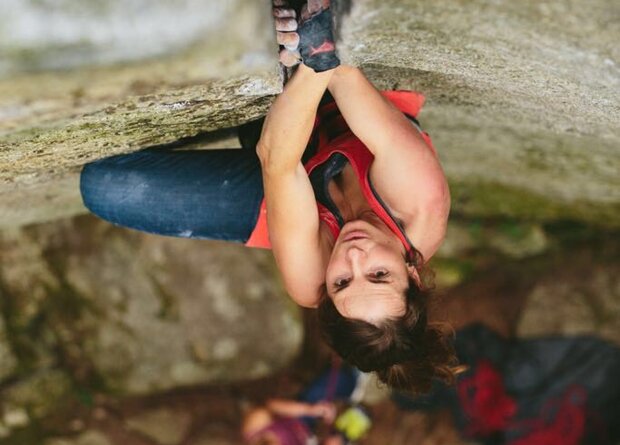

A very important element is the belay itself: Once at the top, the climber attaches the rope and then lowers themselves back down to the ground. There are many systems for this around the world, but the gold standard is two bolts connected by a chain. The rope must then either be threaded through a ring or, as is now standard at Climbers Paradise Tirol, conveniently clipped into a carabiner.

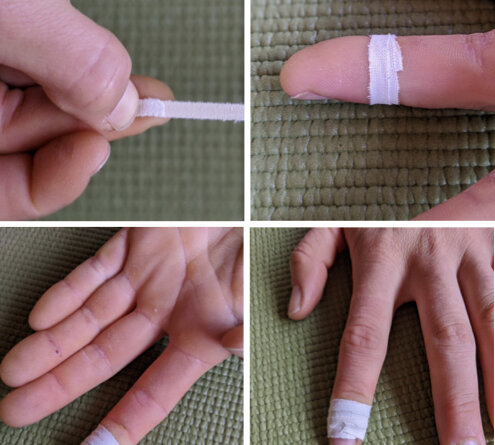

"Depending on how busy a route is, a carabiner will wear out over time due to rope friction. This results in a typical notch on the underside. However, if this notch gets too deep, it can become dangerous: The edges become increasingly sharp and, in extreme cases, can damage the rope," explains Martin. That's why it's a very important task for the maintainer of the climbing gardens to check the belays. And, like today, to replace the belay carabiners if necessary.

Martin removes the old, worn carabiner and takes a brand new stainless steel carabiner from the Tyrolean company AUSTRIALPIN out of his rucksack, turquoise gate. The opening is always at the front, and to prevent the carabiner from twisting, Martin uses a hammer to hammer in a safety pin. "Sodala, so the belaystation is in perfect condition again for the next two or three years - depending on how much the route is climbed," says Martin proudly.

Thanks to the material from Climbers Paradise partner AUSTRIALPIN, only EN 959 standardized material "Made in Austria" is used everywhere. A contribution to greater safety and added value in Tyrol!

It gets loud when the entire stand is changed: The Hilti drives into the limestone almost like butter, briefly removes the drilling dust from the hole, inserts the anchor, attaches the lug, tightens, done. "You can almost hang a car on it now," smiles Martin. The position of the anchor point is also important: on the one hand, the rock itself must of course be rock-solid, so Martin gently taps the rock in several places with a hammer.

"You can clearly hear a singing sound, so you know that the rock is okay. But if it sounds like a bump, you shouldn't drill in that spot," Martin knows from long experience. On the other hand, it is also ideal to place the stand behind a small belly so that it is better protected from falling rocks. And it is also cleaned up afterwards; Martin removes the drilling dust with a brush.

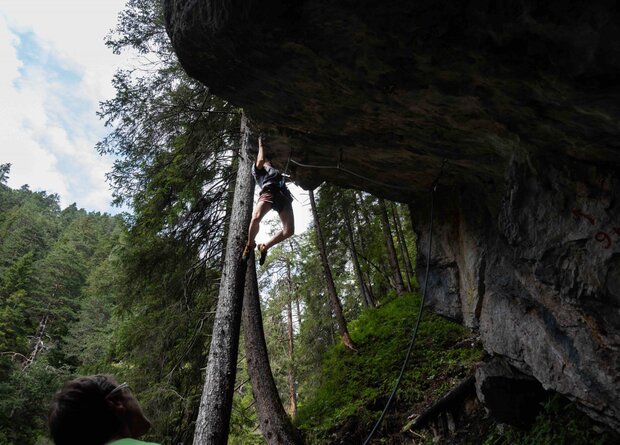

Sometimes new hooks have to be set. For example, if a rock scale becomes loose over the winter and has to be torn out. Then the old fixed point usually no longer fits and has to be "re-drilled".

Shiny pitons, who actually pays for them?

Once the belay is complete, Martin ropes himself from bolt to bolt and checks each one. Tightens a nut here and there, taps the rock for strength with a wrench. And then: new route, new game!

After just one route, you get an idea that this is going to be a labor-intensive day. There are almost 120 routes in the Rote Wand above Karres, and each route has ten or more bolts, depending on its length. Taken together, that's a huge pile of material in the wall that needs to be maintained. This raises the question: who actually pays for all this?

Climbing gardens are often created organically by motivated locals and the equipment is financed out of their own pockets. In the official Climbers Paradise Tirol climbing gardens, however, there is always a clearly defined maintainer who takes care of maintenance at regular intervals. This is commissioned and financed by the relevant tourism association, which in the case of Karres is the TVB Imst. And maintaining a high standard of equipment naturally costs money: "A stand with a carabiner costs around 30 euros, a hook with an anchor around three euros, that's quite a lot," says Martin.

When the day's program is finished, Martin takes the opportunity to test the routes with the shiny new bolts himself. He can finally put away all his tools and put on a normal climbing harness. At the end of the day, Martin climbs a few enjoyable routes in the sixth degree of difficulty, "wenn ma scho mal da ist", high above the church tower of Karres. Afterwards, he is already longing for a shower, covered in a layer of dust from top to bottom.

On the way back, he takes his red barrier tape back with him, job done. So that the next climbers can come and simply do one thing without a thought for safety: Climb without a care in the world and have a great day out in the fresh air.

It is understandable that carabiners are among the most maintenance-intensive elements in the Climbers Paradise climbing gardens. If they are worn down to a maximum of 1/3, they are replaced immediately. Sometimes this happens up to 2 times per season!

The Climbers Paradise Tirol association is committed to the quality assurance of the climbing infrastructure in all 15 regions and in over 130 sport climbing gardens. If something does go wrong, there is a central danger reporting point on the Climbers Paradise Tirol website where anyone can report any damage.

5 questions for mountain guide Martin Gstrein Do I need special training to maintain a KG?

No, but you should definitely attend a drilling course. Climbers Paradise organizes high-quality internal training courses for us, where we always learn a lot. The "Climbing Garden Manual", which was revised and reissued in 2019, describes the quality standards for climbing gardens and bouldering areas in detail.

For those who are interested, there are also drilling offers from the Alpine Club or private providers.

How do you become a climbing garden warden in Climbers Paradise?

In my case, the tourism association approached me because they knew about my expertise and local knowledge. However, interested parties can also approach the responsible TVB on their own initiative and simply make an inquiry.

What qualities are important?

Conscientious and clean work. A deep understanding of how to recognize and remove sources of danger such as loose rocks or trees. A sustainable approach to nature.

How often is a climbing garden in Tyrol maintained?

In the case of Karres, it is twice a year. However, this can vary slightly depending on the climbing garden, but at least once a year.

What is important in terms of material?

Only use tested and certified equipment, for example from Climbers Paradise partner AUSTRIALPIN.

Peter Manhartsberger, Quality Manager at Climbers Paradise Tirol partner AUSTRIALPIN, says: "Our greatest asset is the quality of our products. You can only have them in your hands if you manufacture them completely yourself. That's why all metal products, from development and tools to series production and quality assurance, are made in-house. We focus on quality made in Austria!"

Link Tips from our author Simon Schöpf on the topic: Drilling standards: www.alpenverein.at/portal/berg-aktiv/sportklettern/sicherheit/einbohren/normen.php Overview of AUSTRIALPIN drilling material: www.austrialpin.at/produkte/anschlagmittel-bohrmaterial-eisschrauben/